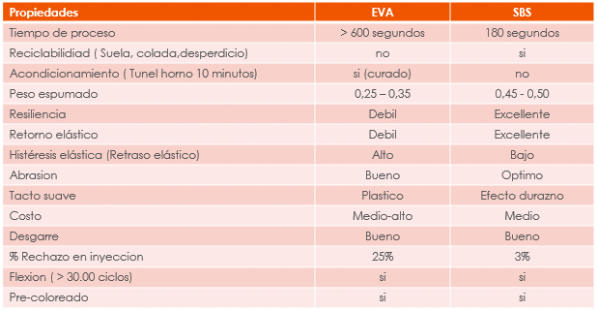

Difference between SBS and Foamed EVA

Elastomers TPE > Blocks

Do you understand the difference between SBS and expanded EVA thermoplastic elastomers?

The styrene-based thermoplastic elastomer (SBS rubber) is a triblock copolymer based on styrene-butadiene, a unit of long sequence of the main chain, and then covalently bonded to each other formed by the copolymer. SBS: synthetic thermoplastic elastomer obtained by the polymerization of a mixture of styrene and butadiene. It should not be confused with styrene-butadiene rubber, commonly known as SBR, which is not a thermoplastic.

SBS block copolymers, is a precise polymer chains, with a sequence of styrene repeat units, labeled in a sequence of butadiene repeating units and topped with another block of styrene units, to give a block of styrene-styrene copolymer butadiene-styrene (SBS). This gives the material the ability to retain its shape after being stretched. The SBS offers an excellent coefficient of surface friction, little permanent deformation, high tensile strength. The material can be temporarily deformed by compression or elongation, but when these forces cease, the material returns to its original shape

EVA, sometimes known as PEVA, polyethylene-vinyl acetate, is a polymer-based material consisting of ethylene and vinyl acetate copolymer. EVA also popularly known as expanded rubber or foam rubber. The different proportions of the two comonomers affect all the final yields of the plastic material which, in any case, are quite similar to those of the LDPE. EVA is a lightweight material with a low cost and, at the same time, it is highly versatile and is used in many different ways. A softer EVA will have, compared to a harder EVA, a worse resistance to abrasion and in an outer sole will have a shorter life but greater comfort. Depending on the purpose, there are many different ways to make EVA. In addition, plastic foams also have many advantages, such as: light weight, insulation capabilities (sound and heat), energy absorption (impact, impact and vibration), buoyancy and elastic properties in certain cases.

Thermal Properties

The glass transition temperature (Tg) of the PB polybutadiene blocks is typically -90 ° C, while the Tg of the polystyrene blocks is + 100 ° C. Therefore, at any temperature between -90 ° C and + 100 ° C, SBS will act as a physically cross-linked elastomer. The operating temperature is guaranteed from -55 ° C to + 70 ° C.

The melting point of the EVA decreases as the VA content increases, therefore the copolymer usage temperatures are lower compared to the corresponding homopolymer (LDPE). The maximum value for the temperature of use of an artifact is less than the temperature softening Vicat. Temperatures as for all thermoplastic polymers, depend on the duration and level of mechanical stresses to which the artifacts are subject when exposed to heat. As the temperature increases, the conductivity temperature decreases until it reaches a plateau near the melting point.

Physical-Mechanical Properties

Polystyrene is a tough hard plastic, and this gives SBS its durability. The polybutadiene is rubbery, and this gives SBS its rubber-like properties. In addition, polystyrene chains tend to cluster. When one styrene group of one SBS molecule binds to one group, and the other polystyrene chain of the same SBS molecule joins another group, the different groups join with gummy polybutadiene chains. This gives the material the ability to retain its shape after being stretched. The SBS offers an excellent coefficient of surface friction, little permanent deformation, high tensile strength. The material can be temporarily deformed by compression or elongation, but when these forces cease, the material returns to its original shape. SBS thermoplastic elastomers thus possess elastomeric properties but are processed as plastics.

The properties of EVA copolymers are mainly determined by the vinyl acetate content and the degree of fluidity. An increase in VA content increases the density, transparency and flexibility of the material, while reducing the melting point and hardness . The ethylene-vinyl acetate copolymer (EVA) is a very elastic material that can be sintered to form a porous material similar to rubber, but with excellent strength. It is three times more flexible than low density polyethylene (LDPE), showing a tensile elongation of 750% with a maximum melting temperature of 96 ° C.

Chemical properties

SBS resists stress cracking well to acids, hydroxides, methanol and ethanol, absorbs oil, fats, aliphatic hydrocarbons. On the other hand, they do not avoid polar hydrocarbons, aromatic hydrocarbons, carboxylic acid, gasoline, ASTM oil No. 1 Paraffiic, ASTM Aromatic No. 3 oil, toluene and benzene. Good resistance to water but poor resistance to water vapor. Low resistance to oils (animal and vegetable). The unsaturated chemical nature of SBS rubber makes XPRENE B sensitive to the heat action of UV rays and ozone, but the use of special additives makes it possible to improve the resistance to these effects of the environment.

EVA copolymers due to their polar nature, they absorb small amounts of moisture. The absorption of water increases with the increase in VA. Resistance to surfactants increases as the VA content decreases in degree of fluidity. EVA copolymers are permeable to gases and vapors. EVA copolymers can be damaged by atmospheric agents and in particular by ultraviolet radiation from sunlight.

Processibility

The SBS belong to the class of thermoplastic elastomers that possess the mechanical properties of rubber at room temperature and the processing capabilities of thermoplastics. The SBS are similar to rubber without being cross-linked, so it is easy to process them to achieve useful shapes, usually it is processed more or less at 140 - 200 ° C. SBS can be easily molded by means of injection, extrusion or molding, on injection, blow molding, co-staggio, overmolding, K2.

During the processing of the EVA, in order to avoid polymer degradation and acetic acid formation, the residence time of the melt in the machines the processing must be limited and the processing temperatures must not exceed the critical degradation values of the polymer . possono essere lavorati secondo i procedimenti usuali per materiali termoplastici, con condizioni paragonabili a quelle di LDPE, ma con temperature di lavorazione più basse. Le condizioni di lavorazione sono influenzate sia dal grade di fluidità che dal tenore di VA. In the case of foamed EVA the cycle time is very high compared to the foamed SBS (3/4 times).